Environmental management model for small dairies in the Industrial Corridor of Boyaca (Colombia)

Keywords:

agroindustria, pequeña empresa, medioambiente, cadena agroindustrial, gestión. (es)Downloads

This research addresses the general objective of environmental issues, focusing on the Environmental Management System model that can be applied to small businesses in the dairy industry in the Industrial Corridor of Boyaca, for which the Environmental Management Model based on the NTC ISO 14000 Standard was created. This is a case study of 10 small dairy companies legally established in the study area. The research results are presented initially with a description of the context and specific means of dairy production activity in the Industrial Corridor of Boyaca; a situational diagnosis was performed for the dairy chain of the department, and likewise the study configured the profile and characterization of the administration and environment of these companies in the study area, using the information collected through a survey of the businesses as the input. With the information obtained in the diagnosis, the Environmental Management Model for these organizations was designed.

1 Universidad Nacional Abierta y a Distancia (UNAD). Sogamoso (Colombia).

2 Sectional Duitama, Universidad Pedagógica y Tecnológica de Colombia. Duitama (Colombia).

3 Department of Agronomy, Faculty of Agronomy, Universidad Nacional de Colombia. Bogota (Colombia).

4 Corresponding author. luisfeliperodriguez@yahoo.com

Received for publication: 18 August, 2009. Accepted for publication: 1 March, 2012.

ABSTRACT

This research addresses the general objective of environmental issues, focusing on the Environmental Management System model that can be applied to small businesses in the dairy industry in the Industrial Corridor of Boyaca, for which the Environmental Management Model based on the NTC ISO 14000 Standard was created. This is a case study of 10 small dairy companies legally established in the study area. The research results are presented initially with a description of the context and specific means of dairy production activity in the Industrial Corridor of Boyaca; a situational diagnosis was performed for the dairy chain of the department, and likewise the study configured the profile and characterization of the administration and environment of these companies in the study area, using the information collected through a survey of the businesses as the input. With the information obtained in the diagnosis, the Environmental Management Model for these organizations was designed.

Key words: agribusiness, small business, environment, agroindustrial chain, management.

RESUMEN

Este estudio de investigación aborda como objetivo general el tema medioambiental centrándose en el modelo del Sistema de Gestión Ambiental que puede ser aplicado a pequeñas empresas de la agroindustria láctea en el Corredor Industrial de Boyacá; para ello se estructuro un Modelo de Gestión Ambiental basado en la Norma NTC ISO 14000. Se trata de un estudio de caso de 10 pequeñas empresas lácteas legalmente constituidas en la zona de estudio. Los resultados de la investigación, se presentan inicialmente haciendo una descripción del contexto y medio especifico de la actividad productiva láctea del Corredor Industrial de Boyacá; se elaboró el diagnóstico situacional de la cadena láctea del departamento; así mismo se configuro el perfil y caracterización administrativa y ambiental de estas empresas en la zona de estudio tomando como insumo la información recopilada mediante encuesta aplicada a los empresarios. Con la información obtenida en el diagnóstico, se diseñó el Modelo de Gestión Ambiental para este tipo de organizaciones empresariales.

Palabras clave: agroindustria, pequeña empresa, medioambiente, cadena agroindustrial, gestión.

Introduction

The research was conducted from an analytical perspective and approached as a case study for a group of 10 small companies (Ley 590 of 2000) of the dairy industry in the Industrial Corridor of Boyaca (Tunja, Duitama, Paipa, Sogamoso, Bethlehem and Firavitoba). This agroindustrial activity is a link in the dairy chain that has considerable economic impact on the department of Boyaca. To prepare the profile of these organizations, a survey was used, which was complemented by a literary review on environmental trends in relation to producers, traders and processors; striving to rethink the way the work is done and highlighting environmental issues as a competitive advantage for the future (Funiber, 2005).

Notably, the use of appropriate technology, hygiene programs and safety have been encouraged in recent years in Colombia, in order to try to reduce problems in the different production processes and in particular in relation to operations such as handling raw material, processing activities and thus the role of people involved in such processes, revealing the fact that, although implementation of clean production has begun, a greater awareness about the environmental issue is still lacking (Ministerio de Comercio Exterior, 2005).

Clearly, dairy processing companies in the Industrial Corridor of Boyaca must adopt effective and efficient strategies to minimize errors that affect this activity and its environment, as in the case of environmental problems caused by mismanagement and the lack of importance given by the companies to such situations.

Environmental management should be viewed as a very useful tool for the dairy industry, both economically and commercially. They must strive to mitigate, correct and compensate for negative environmental impacts, and add value to products processed by a program of environmental management (Ley 99 at the Congreso de la República de Colombia, 1994).

Agribusinesses produce multiple products and use input diversity, which makes it a heterogeneous sector. In dairy companies, it has been established that raw materials, due to their organic nature, are easily damaged, affecting handlers, the surrounding community and consumers. Considering this and with the aim of providing a possible alternative, an Environmental Management System (EMS) model was formulated that leads to the implementation of the in the dairies, which will benefit the environment. (Acercar, 2006) In order to make the dairy companies in the Industrial Corridor of Boyaca competitive, this research aims to: develop a model of environmental management for small dairies in the Industrial Corridor of Boyaca, in order to define lines of action to produce a friendlier environmental management for the context of these organizations. The specific objectives were defined as follows:

• Characterize the dairy chain.

• Develop an environmental situation assessment.

• Characterize the fundamental elements of the structure of an appropriate environmental management model for lacteal agribusiness small companies.

• Define the procedure or the steps for the implementation of the environmental management system in the lacteal agribusiness small companies.

Research methodology and procedure

This research used a case study with qualitative, quantitative and descriptive methods focused on a small group of 10 dairy companies located within the Industrial Corridor of Boyaca, which constituted the target population of the study and therefore the units of analysis, characterized by the similarity in the agribusiness management process of processing milk and also by lawfully registration with the Camara de Comercio (República de Colombia, 2000).

For the collection of information, a questionnaire with open and closed questions was used, surveying producers, entrepreneurs and managers, and interviewing experts in environmental management from public entities. To have solid evidence on the characteristics of the research units, this research used direct observation of the studied companies and secondary sources such as specialized books, journals and white papers from the Ministerio del Medio Ambiente, Corpoboyacá, such as the Plan de Ordenamiento Territorial (POT) for the cities of Duitama, Sogamoso and Tunja.

Context and specific means of the dairy chain of Boyaca

Clearly, to address the environmental issue in small business, it is important to first make a brief description of the environment where these organizations are active. The department of Boyaca is principally agricultural, rich in water and notably for its moors and deep rooted peasant population. The Industrial Corridor has become a catalyst for the areas: economic, social, cultural and political and innovative; creating opportunities and cultural radiation over most of the department, which has serious disadvantages for improving the quality of life for the majority of the population, with the absence of external economies of scale and feasibility. The protectionist model that created the local industry led to the abandonment of vocations such as the wool textile industry, vineyards and olive oil (Secretaría de Planeación Duitama, 2006).

The Industrial Corridor of Boyaca is crossed by the Chicamocha river basin, which satisfies the need for drinking water of 17 municipalities, maintains production processes of 6 large enterprises and 76 medium-sized enterprises, which generate more than 80% of the industrial employment, and sustains the production processes for more than 36,000 ha of agricultural crops, among which are potatoes, vegetables: onions, cabbage, lettuce, broccoli, spinach, carrots and fruits: peach, plum, blackberry, feijoa (pineapple guava); most characterized by the highly erosive tillage system, (15,391 ha). It is noteworthy that 7% of the watershed area has severe erosion (Corpoboyacá, 2007a).

Demographic effects produced by the segmented nature of the business and industrial activity of the Industrial Corridor are associated with the phenomena of population concentration and economic activities in urban areas, improper land use, disorderly urban growth and high rates of unemployment and insecurity. From the point of view of the territory, the concentration of manufacturing activities, transportation, commerce and agribusiness favor an agglomeration of a population that generates distortions and deficiencies in the use of urban space.

The chaotic arrangement of housing and essential public services constitutes the main threat and causes various forms of environmental and social deterioration of the municipality (Secretaría de Planeación Duitama, 2006). The strong rural tradition of Boyaca is noteworthy, characterized by its hardworking and patriotic inhabitants. The department is home to a society whose members have almost been exclusively farmers since its beginning. For over four hundred years, the people have preserved their traditions and ways of life with little social change. The inhabitants have remained loyal to agriculture and still characterize themselves as rural (Fals, 2006).

Among the problems suffered by the inhabitants of the Industrial Corridor as identified by state agencies are: growing unemployment of skilled and unskilled labor, a deficit in the water supply, depletion of water sources, pollution in the environment and water, food insecurity and displacement (Secretaría de Planeación Duitama, 2006).

Industrial Corridor residents have competitive disadvantages such as difficulty to undertake partnership projects, poor training and lack of business sense; due to the establishment of large companies like Paz del Río in Belencito, Sideboy in Tuta, Bavaria in Tibasosa, Postobón and Coca Cola in Duitama and, in the 70s, Sofasa in Duitama, which resulted in heavy reliance on wages (Agudelo, 1998).

Diagnosis of the dairy chain of Boyaca

By volume, Boyaca is a department important to national milk production. It produces about 15,330,000 L d-1, a volume important for consolidating top and new markets in this economic sector (CCI, 2010). The department has distinct zones in milk production: Valle de Chiquinquirá and the Industrial Corridor have the highest number of dairy cattle and specialized herds. Other areas such as the Provincia de Norte y Gutiérrez, La Libertad, Occidente, Valle de Tenza, Márquez, among others, have no specialized livestock and generally use crossbreds. Güicán and Cocuy are areas with good genetic management but have great difficulty in transporting product due to the state of their roads, choosing to do the processing of milk in the same place as production, especially for cheese and butter which are then transported to Bucaramanga and Cucuta (Corpoica, 2009).

The first link of this chain basically refers to the management of the herd and continues with milking, transport of raw milk, transformation process, transport of processed products, sale of processed products, consumption and waste disposal; comprising secondary, tertiary and quaternary links of the dairy chain (Roldán, 2010).

The critical points in the dairy chain in the Industrial Corridor of Boyaca are livestock management within the herd, such as nutrition, health management and milking, since appropriate hygienic standards are lacking. It is noteworthy that this work is not undertaken with the responsibility that is required, especially in small farms, which comprise most of the productive units, due to the smallholdings of the foothills in the department.

Characterization of EMS for small dairies in the Industrial Corridor of Boyaca

The small businesses surveyed showed that the principle economic activity is the processing of milk, producing products such as cheese, yogurt, butter, caramel and pasteurized milk. Family-owned businesses represent 60% of the enterprises, where most of the employees come from the nuclear family; 20% are limited liability companies, showing a somewhat structured administrative organization. The remaining 20% are sole proprietorships. It should be noted that family enterprises are efficient production units through the continuous training received by the members and from production experience.

Management of the family-owned businesses is not homogeneous since the managers or owners do not have the same level of education, resulting in different management and transformation processes.

This study established that the production process of fresh cheese is the most important, particularly matured cheese in small quantities because of its price and select market. Making cheese has a strong bearing on environmental management, related to the high volumes of whey, a byproduct that can be further processed to obtain other products or be used as pig feed. Unfortunately, most of these companies do not reuse it but pour it into fields of infiltration or sewer systems, which then flow into the Chicamocha river, causing pollution; hence whey is considered one of the biggest pollutants of the groundwater.

The 100% of the studied companies performed quality control of the raw material (milk), effected on a receiving platform, because the milk comes from several herds and mixing them can damage the product. Additionally, the milk is weighed and the hygienic quality, composition and possible presence of adulterations are controlled, using rapid reduction tests of odor and alcohol. This is where the first negative environmental impact of the transformation process is generated by washing the containers, which involves the first dumping directly into the sewers and subsequent pollution of aquifers. When the milk is transported in tank cars to the plant, milk spillage is minimal because it goes directly to the collection tank on the ground. However, contamination occurs with the washing of the tank of the vehicle.

The 90% of surveyed companies do quality control on the finished product. A review of process control from the collection of the raw material (milk) to the finished product reveals neglect in some of the process operations, generating waste and leading to economic losses and generation of negative environmental impacts.

In addition to the production area (the epicenter of such companies), the studied operations take into account the areas of market management, finance and human resources. In the market area, 40% of the companies operate at the municipal level, placing dairy products in supermarkets, convenience stores and neighborhood shops. The 30% do so at the departmental level and the remaining 30% market their products in cities like Bogota and Bucaramanga. Only 20% of the companies are seeking new markets and 10% of them are considering certification to export their products.

By analyzing the type of financing, one sees that the sector has cultural limitations. Thus, owners prefer to maintain production levels and not expand because they do not trust or do not know how to handle the banking financial system, saying they prefer to opt for other types of financing such as reinvestment, third party loans or self-investment. For homeowners, the most important objective is to produce and sell without clearly establishing the profitability and benefits generated by the companies. As these companies do no clearly manage projects, most investments are set according to the requirements presented by production development, i.e. if demand increases, they increase raw material purchases.

Regarding the management of human resources, 30% of companies rely on an industrial safety committee. The 70% do not give due importance to this issue and display a lack of implementation of safety management standards and occupational health processes required for certification. The 10% of the companies use part of the work time to train employees in risk management, while 90% do not train employees and lack the necessary elements for product handling.

Before starting the analysis of the small dairies in the Industrial Corridor of Boyaca, regarding the characteristics of the environmental management system, it should be noted that in 1993 the Ministerio del Medio Ambiente y la Corporación Autónoma Regional de Boyaca (Corpoboyacá) created, (Corpoboyacá, 2007a) and afterwards, environmental management guidelines were established that are mandatory for companies that start after that time. Since 80% of the studied companies were created in previous years, they are in the transition period for the implementation of these standards. Fortunately, there are managers with a futuristic vision with defined productive projects, which are entering new management trends such as certifications in quality management, good manufacturing practices and environmental management.

For companies created after 1993, the conditions required for operation by Corpoboyacá are: land use planning issued by a municipality and/or conservatorship, construction license copy and approved plans, approved certificate for industrial water use in the village aqueduct according to Decreto 1541/78 (Cámara de Comercio de Bogotá, 1998), which regulates the use of water. Among the requirements for agribusinesses is the dumping plan according to Decreto 1594-1584 (dumping of sewage) (Cámara de Comercio de Bogotá, 1998), which determines the final disposal of domestic wastewater, industrial wastewater and storm water, which must take into account the handling of by-products such as whey (Corpoboyacá, 2007b).

It is very important to note that 40% of the studied small dairy companies are located within the city limits of municipalities and according to the provisions of the Land Management Plan (POT) or the land use patterns of municipalities in the Industrial Corridor of Boyaca, these agribusiness companies should relocate in the medium term according to the established land use plans. These land plans and schemes are coordinated with Corpoboyacá, who directly monitors the environmental performance of these agribusinesses (Corpoboyacá, 2007a)

The 70% of those surveyed do not contemplate, within the organizational structure of their companies, the environmental area. Thus, only 30% are advancing the issue and applying training strategies with the aim of improving processes and procedures as illustrated in Fig. 1. Business operators are apathetic toward understanding and managing the environmental issue, because for them, it generates increased costs which, given the size of the company and its production levels, cannot be covered, i.e. there is a lack of knowledge about the benefits generated by good manufacturing practices GMP.

One factor that is at odds with the establishment of environmental processes is the lack of corporate commitment due to the high costs this decision arguably entails (Fig. 2). If there was a well established guild in this agribusiness, awareness among the companies would most likely be raised, through training, of the importance considering the environment in their policies.

The water used in the washing and sanitizing operations for these companies are usually discharged into the sewer of each municipality, and these discharges go into the Chica- mocha river which, in the dry season or summer, becomes the biggest sewer in the department, since it collects all the wastewater from the nearby municipalities.

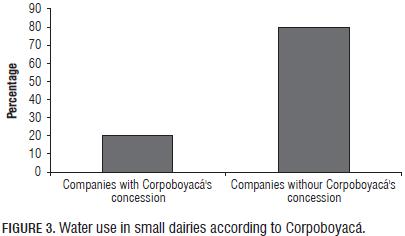

Corpoboyacá, as an autonomous state entity, grants concessions for water management (PAT 2007 - 2009). Under these guidelines, 20% of the companies surveyed enjoy this perk, while the remaining 80% do not have this benefit because the company is not properly registered or has not notified this entity even though most of these organizations have operated for over 15 years (Fig. 3).

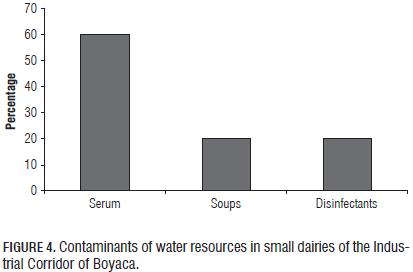

As Fig. 4 shows, the three major contamination residues in dairy are whey (60%), soap residues (20%) and disinfectants (20%). The main disinfectants that are used are chlorine, iodine and quaternary ammonium compounds; the soaps used are citric acid based, nitric acid, caustic soda and sodium hydroxide. Aseptic processes do not always succeed because the right amounts and/or mixtures recommended by the manufacturers are not used, causing increased water pollution.

The whey discharged into streams causes alterations in the dissolved oxygen, impoverishing and affecting animal and plant life. This alteration is due to the oxidation of organic material and is measured through the biological oxygen demand in 5 d (BOD5). A liter of whey requires about 40 g of oxygen, which is very similar to the demand generated by ¾ of an individual per day. The BOD5 of whey originates from protein (10 g of oxygen) and lactose (30 g of oxygen) (Almanza and Barrera, 1995).

Importantly, 80% of enterprises, as already established, do not consider environmental management as important in the process of transformation, i.e. there is no awareness of waste management, or other decontamination operations, since only 20% of surveyed companies manage actions and procedures to minimize contamination of aquifers, such as with the use of fat traps, preventing waste and since only 10% have plant wastewater treatment (Fig. 5).

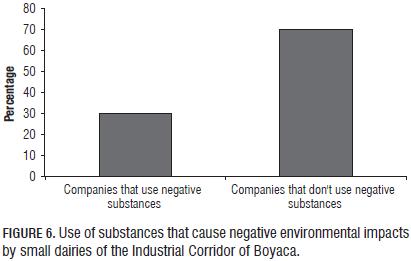

As to the use of substances causing negative environmental impacts, we see a paradoxical phenomenon, as illustrated in Fig. 6, which shows that only 30% of the companies claim use of negative substances and the remaining 70% said that the products used are not harmful to the environment, probably due to the lack of knowledge on the composition of the products used in the cleaning and disinfection.

The 100% of the companies do not perform environmental assessment, because in most there is no awareness, preventive management culture, or knowledge of the impact generated. Notably, only 20% of companies surveyed made a classification of waste. The remaining 80% do not, but use incineration processes that they believe are the best suited. Others simply are troubled to make the classification and give this responsibility to the garbage collection truck (Fig. 7). In these wastes is the material collected in fat traps, which if not handled with proper disposal, will also generate a negative environmental impact.

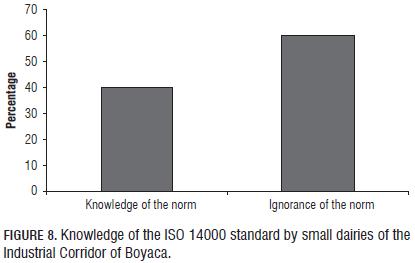

The 40% of the companies are aware of the existence of ISO 14000 and the vast majority of entrepreneurs do not apply it. Additionally, they are apathetic because standards relate to costs and expenses, hence they do not pay attention to the issue, and their attitude is: if there is no obligation to implement it, it is too difficult to do so. Only 20% are willing to implement and work for the competitiveness of the agricultural industry, which presently includes seeking new markets, increasing production and developing new products, for which the implementation of ISO 9001 version 2000 and ISO 14000 have already started (Fig. 8).

Model of EMS for small dairies in the Industrial Corridor of Boyaca

The configuration of a proposed model of EMS is presented as a practical tool that can be applied in a dairy processing company, whether it is micro, small or medium. It is a contribution to the business sector that seeks to facilitate the implementation of the EMS, responding to the guidelines given by the ISO 14000 for management and environmental management. This standard has practically become a requirement for global trade, implementing a unified language for quality worldwide.

Company environmental management systems arise from the need to reduce costs in business organizations through sound environmental management, minimizing the consumption of water, energy, and raw materials, thus decreasing both solid and liquid waste (Epstein, 2000). It is hoped that the application of the proposed model that is illustrated in Fig. 9 will bring to small dairies a proposal to implement cooperative environmental strategies and policies aimed at planning for businesses to reduce environmental impacts through process designs and products to increase the quality of products, the company's profitability and to reduce or eliminate waste (Epstein, 2000).

Using this model provides the tools for analyzing the organization and methods of operation, in order to improve its operation. To achieve this, the organization is taken and deconstructed into its parts. Then each part is studied to determine whether its design and operation is efficient, that is, if each part possesses characteristics that are required and if the role it plays in the system is adequate, or if the function each part fulfills is convenient.

Recommended procedures for EMS implementation in a company

The block diagram of Fig. 10 outlines the steps to be followed for the implementation of the EMS in dairy plants, based on the NTC ISO 14000 standard (Icontec, 2002).

Conclusions

The productive activity of small dairies located in the Industrial Corridor of Boyaca focuses primarily on the development of fresh cheeses, yogurt, pasteurized milk, butter and caramel. These organizations, most of which are family-owned, are examples of notable entrepreneurship actions, despite having some obstacles in their business development due to the absence of a defined organizational structure and the limited availability of both investment and operational capital.

Small dairies in the Industrial Corridor of Boyaca are not homogeneous, especially in managerial and management issues in the areas of financial management and human resources.

The dairy industry in the study area is weak because the culture of the population is characterized by individualism, which makes it difficult to form associations and pursue common goods, to which is added the degree informality seen in small producers.

Small dairies in the industry do not have a defined channel of communication to define the sector's needs and thus seek a dialogue with the government to overcome those needs.

The small dairies are at a disadvantage with larger companies in aspects concerning quality and competitive prices for raw milk, as they cannot offer higher prices and so end up buying lower quality raw material.

A significant percentage of small dairy companies operate with a weak regulatory structure as they have no clarity on standards or legal requirements, this due to lack of support by organizations such as Chambers of Commerce and the autonomous regional associations.

A high percentage of the studied small dairy companies did not clearly show their commitments to the environment, but some are starting to get involved with this issue, because their products have begun to position themselves in niche markets that demand quality certification.

The aquifer system is most affected by these agribusiness companies, which mostly drain into sewers that will lead to the Chicamocha river basin, Boyaca's main river, which has become the biggest sewer in the department.

Small dairies have a weak capacity to identify critical problems of quality, logistics, marketing and, of course, environmental improvement.

Future agribusiness development in the studied area is highly dependent on the adoption of environmental policies, bringing a better production and competition dynamic, benefiting the region.

There is no dairy trade group, since in this branch of production individualism predominates in management practices, under which, options such as collective solutions to improve both general and environmental management are discarded.

Literature cited

Acercar, Unidad de Asistencia para la Pequeña y Mediana Industria. 2006. Ventanilla de asistencia técnica ambiental para la Mipyme. Departamento Técnico Administrativo del Medio Ambiente (DAMA), Bogota.

Agudelo A., E. 1998. La coexistencia de las racionalidades campesina y obrera en el trabajador Boyacense. In: Dombois R. and C.M. López (eds.). En cambio técnico empleo y trabajo en Colombia. Universidad Nacional de Colombia, Bogota.

Almanza, F. and E. Barrera. 1995. Tecnología de leches y derivados. Unidad Universitaria del Sur de Bogotá; UNAD, Bogota. Cámara de Comercio de Bogotá. 1998. Marco jurídico del derecho ambiental en Colombia. Bogotá.

Congreso de la República de Colombia. 1994. Ley 99 de diciembre 22 de 1993, creación del Ministerio del Medio Ambiente. Diario oficial No. 41. Bogota.

Corpoboyacá, 2007a. Informe de actividades 2007. Tunja.

Corpoboyacá, 2007b. Plan de Acción trienal PAT 2007 - 2009. Tunja.

Corpoica. 2009. Ministerio de Agricultura y desarrollo rural. Caracterización de los sistemas de producción de leche del trópico de altura de los departamentos de Boyacá y Cundinamarca. Informe Técnico Final. Bogota.

CCI, Corporación Colombia Internacional. 2010. Caracterización de los sistemas de producción de leche en Colombia año 2009. Servicio de Información Agropecuaria, Bogota.

Epstein, M.J. 2000. El desempeño ambiental en la empresa. ECOE Ediciones, Bogota.

Fals B., O. 2006. El hombre y la tierra en Boyacá. Bases sociológicas e históricas para una reforma agraria. 4th ed. Universidad Pedagógica y Tecnológica de Colombia, Tunja, Colombia.

Funiber, 2005. Fundación Universitaria Iberoamericana. Sistemas de gestión medioambiental en la empresa. Tecnos, Madrid España.

Icontec, Instituto Colombiano de Normas Técnicas y Certificación. 2002. Guía implementación de la norma NTC-ISO 14001. NTC-ISO 14001-14002. Bogota.

Ministerio de Comercio Exterior. 2005. Perfil cadena láctea y sus derivados. Dirección de Competitividad, Ministerio de Comercio Exterior, Bogota.

República de Colombia. 2000. Ley 590 de 2000 sobre mipymes diario oficial. Bogota.

Roldán, D. 2010. La cadena láctea en Colombia. In: Ministerio de Agricultura y Desarrollo Rural, http://www.agrocadenas.gov.co; consulted: March, 2012.

Secretaría de Planeación de Duitama. 2006. Plan de Ordenamiento Territotial Duitama, 2006. Duitama.

How to Cite

APA

ACM

ACS

ABNT

Chicago

Harvard

IEEE

MLA

Turabian

Vancouver

Download Citation

Article abstract page views

Downloads

License

Copyright (c) 2012 Agronomía Colombiana

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.

© Centro Editorial de la Facultad de Ciencias Agrarias, Universidad Nacional de Colombia

Reproduction and quotation of material appearing in the journal is authorized provided the following are explicitly indicated: journal name, author(s) name, year, volume, issue and pages of the source. The ideas and observations recorded by the authors are their own and do not necessarily represent the views and policies of the Universidad Nacional de Colombia. Mention of products or commercial firms in the journal does not constitute a recommendation or endorsement on the part of the Universidad Nacional de Colombia; furthermore, the use of such products should comply with the product label recommendations.

The Creative Commons license used by Agronomia Colombiana journal is: Attribution - NonCommercial - ShareAlike (by-nc-sa)

Agronomia Colombiana by Centro Editorial of Facultad de Ciencias Agrarias, Universidad Nacional de Colombia is licensed under a Creative Commons Reconocimiento-NoComercial-CompartirIgual 4.0 Internacional License.

Creado a partir de la obra en http://revistas.unal.edu.co/index.php/agrocol/.